Hey y’all, I managed to hack together a printer from scratch and I’m struggling to get it to print well. It’s a CoreXY system that’s being controlled by a Octopus 1.1. Dual z screws, the works.

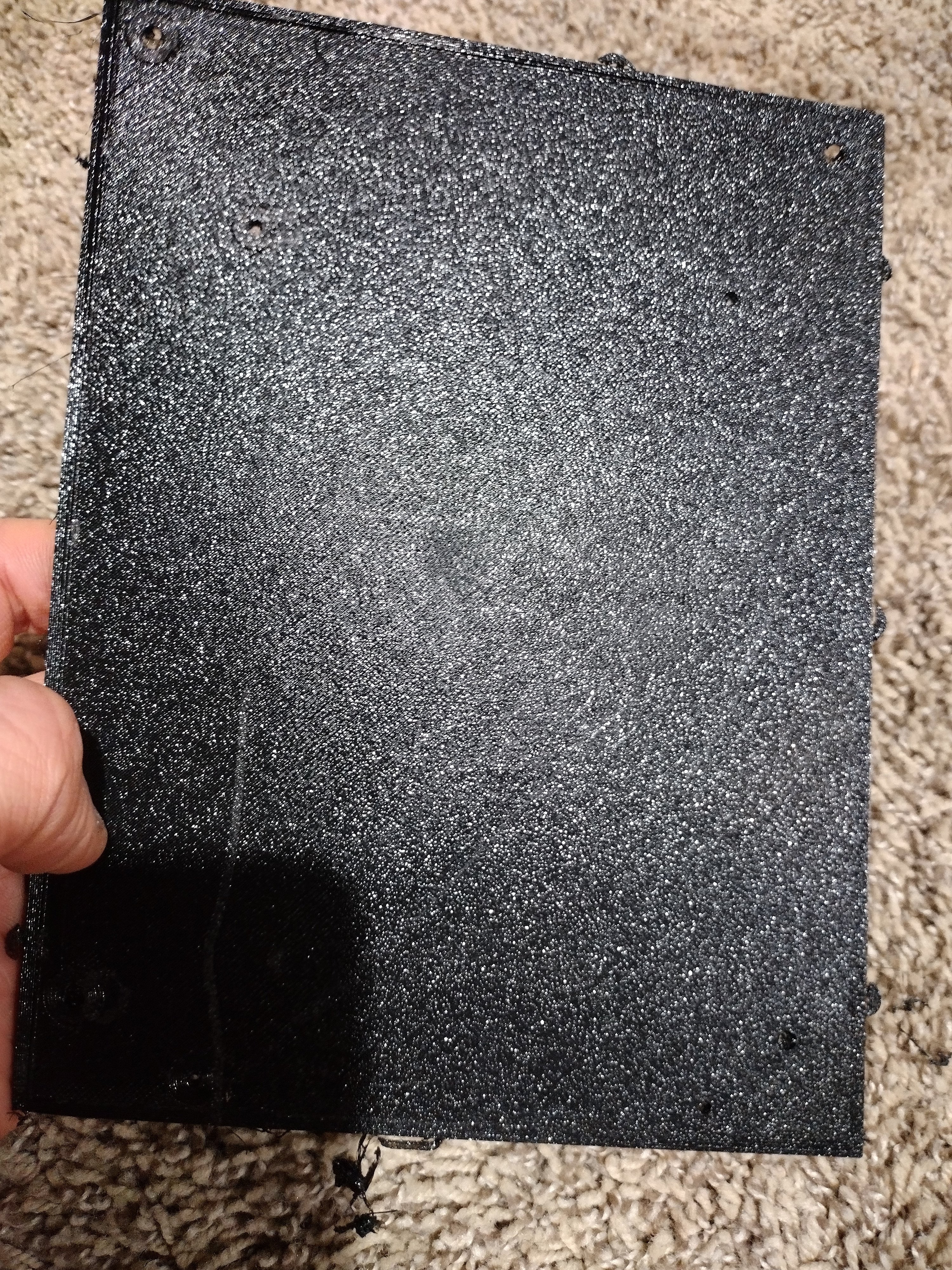

I have it moving under it’s own power and all. It’s able to actually print, but the results are atrocious.

I’m just trying to diagnose what’s wrong here.

The bottom/first layer actually looks kinda good. It’s just completely shredding subsequent layers.

Any advice would be appreciated!

Partial clog, possibly due to not a high enough extruder temp.

Do a few cold pulls and bump your print temp 10

Is your z height calibrated? Is your nozzle dragging as it prints the higher layers?

Is your extrusion calibrated? You may need to bump the extrusion multiplier

I’d be surprised if it was too cold, but I’ve heard stranger. This is PETG at 250. I’ve actually pulled the nozzle and Bowden tube and pushed a very small Allen key through, so it shouldn’t be clogged.

Z height is calibrated, and I’ve calibrated the e-steps for the z axis. I’ve tried disabling the fade height to see if that was doing something but it didn’t seem to make a difference.

I ran through calibrating the extrusion e-steps. It’s feeding 100mm when I tell it to do so. I haven’t messed with the extrusion multiplier, do you have any information about that?

This is quite toasty, at least for the PETG I print. I’m usually at around 240 for my first layer and 230 or 235 for all subsequent layers.

Have you run a temp tower?

https://ellis3dp.com/Print-Tuning-Guide/articles/extrusion_multiplier.html for more info. In a nutshell, you lower it for oozie filament and increase it for more viscous filament. For PETG I lower it some, but the exact amount varies by filament brand and color.

That said, I don’t think this is your issue.

I haven’t run a temp tower. I’m not fully convinced that it won’t damage itself so I’ve been trying to think through it before trying another print.

If you are suffering a clog and/or under extrusion issue the worst I’ve ever seen happen on my printers is the extruder clicking because the e-stepper is trying to step, but can’t. It might not be a bad idea to go over all the connectors in that path. When I finished building my Voron one of the factory terminals in the LDO stepper’s connector had a terminal that was backed out, causing weird extrusion issues.

The print before this one, the blobbing/shreds were tall enough that one grabbed the BLTouch probe and bent it a little. I was pretty mad about that tbh.

I’ll double check my connectors. That’s a solid shout actually.

You only calibrate E, calculate for XYZ.

Calculate the rotation distance for the Z, if it doesn’t move the correct distance when asked you have a broken part.