Hey y’all, I managed to hack together a printer from scratch and I’m struggling to get it to print well. It’s a CoreXY system that’s being controlled by a Octopus 1.1. Dual z screws, the works.

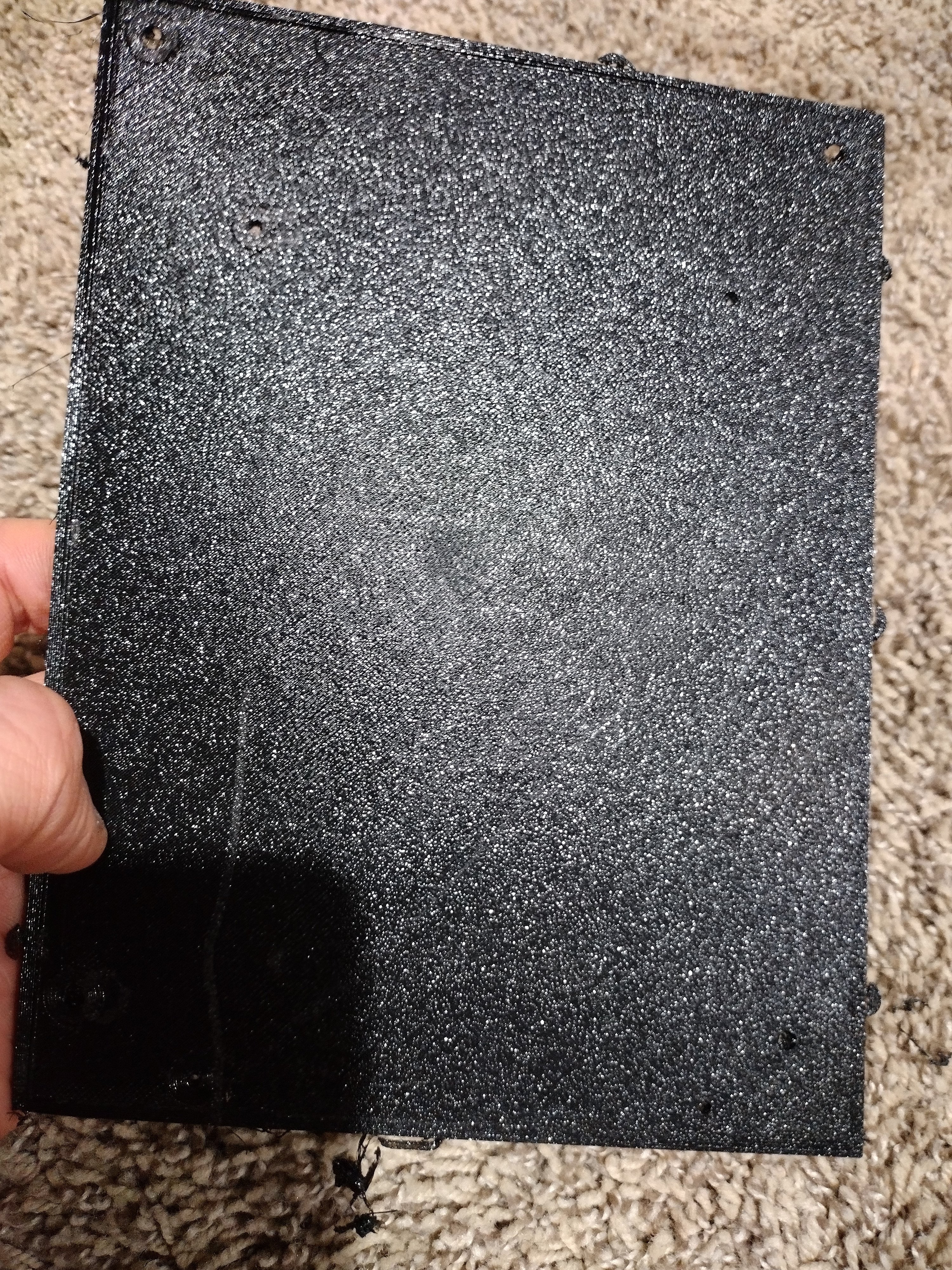

I have it moving under it’s own power and all. It’s able to actually print, but the results are atrocious.

I’m just trying to diagnose what’s wrong here.

The bottom/first layer actually looks kinda good. It’s just completely shredding subsequent layers.

Any advice would be appreciated!

Because I hate when people ask questions and never go back to update their original post when they solve the issue, I’m gonna post an update here and now.

The fix was actually surprising but simple. I ended up moving the second Z axis lead screw carriage mount a bit further towards the motor. That is, the piece that supports the build plate, where it connects to the leadscrew.

Further diagnostics ended up showing me that it was binding, and one of the problems I had later on was that it was binding but only when going up. So I ended up having prints that got progressively more and more stretched out along the z axis.

Moving it to be further in line and loosening a few mount screws to allow the nut to come back to vertical got me to where I needed to be. Hope this helps!