I was thinking they may have a process like 3D metal sintering, using a laser to fuse powdered metal layers. In the very early days of that technology I saw a small polyhedra frame like a ball. The texture was very granulated and it felt like it would crumble if it you rubbed it between your fingers too roughly. But it was titanium and indeed a lot stronger than its appearance suggested.

This was (obviously) a very long time ago back when people were Frankensteining their own printers from components and off the shelf options were few and far between and prohibitively expensive. When the early adopters were losing their minds on the daily trying to calibrate, level and troubleshoot all the gribbles and gremlins. It was quite a deterrent to entering the hobby. I couldn’t imagine then that the technology would accelerate so quickly, to the point where a first time user can unbox, assemble and be printing accurate and tidy prints in under an hour.

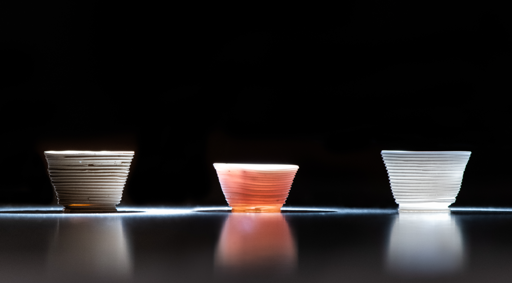

Seeing what is happening with metal and glass printing these days is still blowing my mind. I love that we’re living in a time where there is so much interesting and fun stuff to discover and so much of it is being shared instead of hoarded.

My brother’s lab (not at MIT) has been 3D printing optically clear glass for years. They can do all sorts of shapes and figures, though I’m particularly fond of the Yoda heads. If I’m reading this article correctly, the breakthrough they made was with the temperatures they can do it at, and it’s much less to do with the novelty of 3D printing glass. So it’s much less “hey, this is amazing, nobody has ever done this before,” and far more “we did this cool thing in a new and harder way!”

Low temp has a lot of implications for spreading this technology. Being able to print complex glass shapes at low temperatures can open up all kinds of cool applications that wouldn’t be possible at high temps.

we did this cool thing

Haaa, get it? Low temps.

I’m done.

I regret not catching that myself, that’s good 😁

First time for them

https://oxman.com/projects/glass-3d-printing

Sorry for the link but it’s glass printing 4 years ago

https://www.reddit.com/r/3Dprinting/comments/mv6j9n/my_molten_glass_3d_printer_5mm_layers_and_the/

Sounds like it would be a super fun nozzle clog situation.

Is it inside an annealer? There’s not much techy info in these links, but cool as hell.

Great question. I just know I had seen glass printing before and maybe it’s the lower temperature or whatever that is the breakthrough but it isn’t new in practice.

#JustMITthings

This inorganic composite glass is made of inorganic materials

Department of redundancy department

The first rule of tautology club is the first rule of tautology club.

250C is not low temp for 3D printing tho, noticed that in headline.

sure that is low temp for glass aber above the PLA, ABS, ASA temps i run in vorons.

Whut? Basically every 3D printer does print way above that (300°+X is the industrial norm for more advanced new printers now e.g. Centauri Carbon, Artillery M1 Pro, BL, etc.). 250° is absolutely nothing out of the ordinary these days and can be achieved by basically every 3D printer a major brand brought out in the last two years. Even the A1mini can do so.

Polymaker’s ASA is recommended to be printed at 250° and Formfuturas ASA, BL ABS, Formfutura ABS(reTitan), Fiberology, For Polymakers ABS the lowest temp recommended starts at 245°C, goes up to 265.

Most Nylons, PCTG start above 250°C as well. And let’s not even start about proper high Temperature materials like PEEK,ULTEM,PEI.

Don’t get me wrong,but maybe your temp sensor is off(not unheard off in Vorons) or your settings are off. I have yet to see someone get ASA printed well with settings well below the recommendations.

i was talking about hobby and entry level printing. nevermind. you folks are a lot of fun…

Centauri Carbon: Around 300 bucks Bambu Lab A1 mini: Around 200 bucks

How much more entry level can you get? That’s below most Voron builds, btw.

You came in here with a claim that was simply not valid. The most likely explanation is that your printer is misconfigured. But you keep on generalising your subjective experience towards everyone else,even though you have been disproven.

They stated 250C was for annealing to final product. That’s a temperature any bog standard toaster oven or kitchen oven can do. Sadly, they said nothing I saw about actual extrusion temps.

Glass (some not all) melts at more than 1000 C I think that’s hell of a lot harder to print at than 250 C even Prusa PETG prints at that temp.